Israeli start-up Profuse Technology is ‘revolutionising’ the cell-based meat sector with its small molecule-based media ‘cocktail’. Co-founders Guy Nevo Michrowski and Dr Tamar Eigler-Hirsch explain how the supplement is optimising muscle creation in the lab.

Entrepreneur Guy Nevo Michrowski is a vegan who loves meat. Although tech has now been his life for 25 years, prior to working with computers in a lab, he was working with knives in a kitchen. “I used to be a chef before I started in the tech business,” he recalled.

“Eleven years ago, I became vegan. And I still love meat. So that’s a problem.”

The problem is, in fact, bigger than that in Michrowski’s eyes, who after shunning all animal-based foods realised he was not only in the minority, but that he would continue to be. “People will not become vegans and stop eating meat, because people love meat and believe they need it for protein.”

Indeed, it has been projected that global demand for animal-derived protein will double by 2050, resulting in concerns for sustainability and food security.

The entrepreneur is doubtful plant-based alternatives will ever truly substitute meat by mimicking taste, texture, aroma and nutritional profile. “On occasion, I offer my kids plant-based meat analogues. They’re polite, but basically throw it out the window,” he mused – only half in jest.

Michrowski came to the conclusion that ‘actual’ meat can’t be taken off the menu. But it needs to be produced in a different way, with sustainability and food security in mind. A proponent of the cell-cultivated meat sector, Michrowski – together with co-founder Dr Tamar Eigler-Hirsch – founded Profuse Technology in Northern Israel, where it is a member of the Fresh Start incubator.

Not a cell-based meat company itself, Profuse instead supplies to producers of cell cultured meat.

Activating a biochemical signalling pathway for efficient muscle creation

Unlike Michrwoski, who serves as Profuse Technology’s CEO, co-founder Dr Eigler-Hirsch comes to the business with an academic research background. Dr Eigler-Hirsch is Profuse’s CTO.

While investigating the different regenerative effects of muscle at the Weizmann Institute of Science near Tel Aviv, Dr Eigler-Hirsch found herself ‘playing around’ with muscle stem cells in a lab.

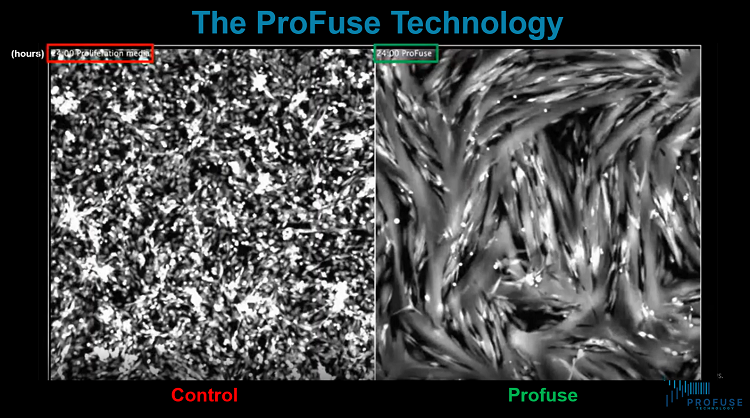

“We identified a molecular pathway in muscle stem cells that regulates the process of muscle formation very strongly and efficiently,” she recalled. Eigler quickly saw the potential this technology could have on cell-cultivated meat.

Improving the efficiency of differentiation and formation of muscle in the cultivated meat industry ‘definitely’ requires intervention, according to the CTO. “It’s a huge whitespace, and that’s where we come in. We enhance this natural biological process by making it more efficient.”

Profuse’s technology works during the differentiation and maturation phases of the myogenesis process. This process – which culminates in muscle creation – typically accounts for 50% of the cost of cultivated meat production.

Applying Profuse’s technology encourages the muscle stem cells to fuse with each other, and to keep fusing until ‘very long’ muscle fibres are created, Dr Eigler-Hirsch explained. This is important given that it is the muscle fibre itself that provides the organoleptic experience and nutritional value when consuming meat, she continued.

A small molecule ‘cocktail’ to help achieve price parity

The ‘cocktail’ is made my combining a ‘mixture’ of materials that ‘push the right buttons’ in the regulation mechanism, CEO Michrowski explained.

“Many of the materials are natural and already used in food. They’re animal component-free small molecules. Many of them are already used in the food industry and some are small molecules that we’ve discovered to be effective.”

Without it, our biological system is naturally ‘protective’ about the stem cell population. With the supplement, that defence mechanism is removed and allows ‘all the stem cells’ to build the protein ‘factory’ in the fibre, Michrowski elaborated. “It makes that natural process happen much faster and at a higher scale.”

The supplement – or ‘Profuse cocktail’ as the start-up calls it – is added to the growth or differentiation media as a single administration. It works in both foetal bovine serum (FBS) and serum-free media.

The result is, according to Profuse, cell-cultivated meat with up to 2-2.5 times more muscle, 4-5 times more protein, reduced production times, and the potential to achieve price parity with conventional meat: Profuse claims its supplement can cut production costs by up to 40%.

Supplement ‘non-detectable’ in end-product

As a B2B company, Profuse is already working with the ‘vast majority’ of leading cultivated meat companies to help reduce costs, improve nutritional values, texture, and protein content. Players are located across the Europe, the US, Israel and the Asia Pacific.

In these companies’ final products, Profuse’s media supplement is ‘non-detectable’. “Only a very small amount is introduced into the process,” the CEO explained. “By the time the meat is harvested, it is basically non-detectable, because the residuals are so small.

“It’s a processing aid, rather than a GRAS material or food additive.”

Profuse is in the process of certifying its supplement with the US Food and Drug Administration (FDA). It expects this process will be completed by mid-2023.

As a processing aid, regulation is less of a challenge for Profuse than it is for cell-based meat companies producing novel foods. “They will have to submit a Novel Food application. [If they use our technology] that will also include our data and regulatory infrastructure, which we are already preparing for them.”

It is also a ‘big challenge’ for the regulator itself, added Guy. However, the CEO is optimistic that once approved, ‘good’ cultivated meat processes can help improve food security and reduce the negative environmental impact of conventional food production.

“We need cultivated meat, [otherwise] we don’t have enough meat to feed the population. Food security is the first thing.

“And the second is the environment: cultivated meat production is more sustainable and reduces reliance on [limited natural resources]. We make that process even more efficient.”

Overcoming the scalability challenge

A common challenge amongst cell-cultivated meat is achieving scale. This is not a direct concern for Profuse, which makes its ‘cocktail’ with materials ‘already produced at high volumes’. “Luckily, we don’t need to build any production scale-ups because the supply chain is already producing those components. So we don’t have a scale-up challenge.”

Indirectly, however, scale remains a hurdle. When Profuse’s customers transfer their technology from lab-scale to a 2L bioreactor, and then up to a bioreactor with ‘hundreds of litres’ of capacity, and eventually up to ‘thousands of litres’, the process changes, the CEO explained.

“We must be sure we’re able to adapt and optimise what we do to their dynamic processes. Different customers are using different approaches on different cells lines and with different species. Some of them use scaffolds, others use printing or suspension growth technology.

“That’s where the muscle [grows], so we must be able to be familiar with those approaches and adapt our mixture. That’s our challenge.”

The CEO continued: “That means working closely with our customers and sharing information. That’s the only way to go when an industry has such a huge challenge ahead of it: you need to work together.”